Discover our QipCam seal inspection systems

We design systems to monitor the sealing process and final seal quality of all kinds of packaged products

A seal inspection system for a 100% accurate check of seal quality

Qipack is an innovative company, specialized in seal check equipment. We design systems to monitor the sealing process and final seal quality of all kinds of packaged products.

In short, our seal check system makes quality inspection of the packaging process reliable, easy, sustainable and relatively inexpensive.

Qipack’s 3 step approach

How we guide your enterprise in reaching its packaging quality targets:

- Audition of the packaging line

- Packaging process improvement

- Online production monitoring

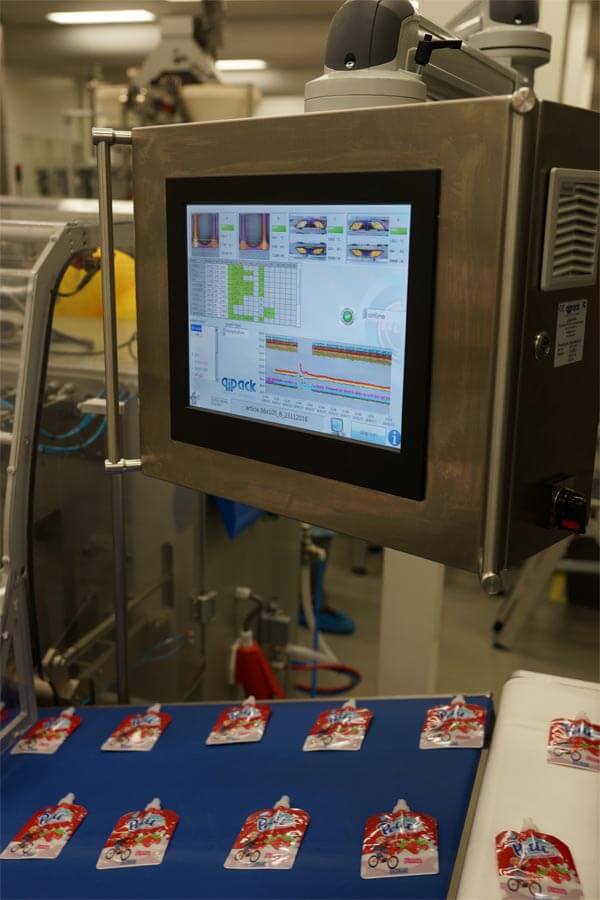

QipCam

The Qipcam consists of the following 3 units:

- High performance infrared camera

- Scans and compares each new seal with the registered good reference seal. Failures will be detected.

- Control PC

- • IP66 Stainless steel enclosure

- • Different IO’s to rejecter

- QipCam software

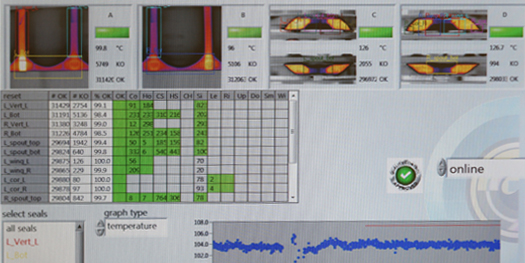

- Analysis of pixels received from the camera translated into a seal quality finger print.

Infrared technology and sophisticated software make the seal check possible

The system for seal inspection is based on infrared technology and sophisticated software. This will offer the ability to continuously check in-line the seal pressure and seal integrity, but also in-line wall thickness control at blow moulding equipment. An extra option is an integrated OEE manager, which can monitor the production process through means of a real-time production status. This software also has an extensive analysis function, so you can save seal check reports for future product packaging inspection. Full tracking and tracing will become an option.

How can we be of service?

Please contact us to discuss the possibilities for your company

Seal inspection to control the production process more efficiently

Our seal check system is able to do more than you think. Our solutions are capable of checking every single packaged item that is produced on almost any type of heat-sealing production lines. We visualize any type of defect, from product in seal, plies in laminate, pressure differences during sealing, to dirt on seal tooling. With this advanced seal and leak detection, you not only detect leaks, but also prevent leaks in your future production processes.

Discover our packaging process improvement

The seal inspection system does not interfere with the production process and does not affect production capacity. There is no limitation to the types of laminate or printing that are used. This also includes alu-based laminates. A demonstration is easily performed without production loss. Do you have questions about our company? We are happy to provide more information or a quick summary regarding seal inspection. Please contact us to discuss the possibilities for your company.